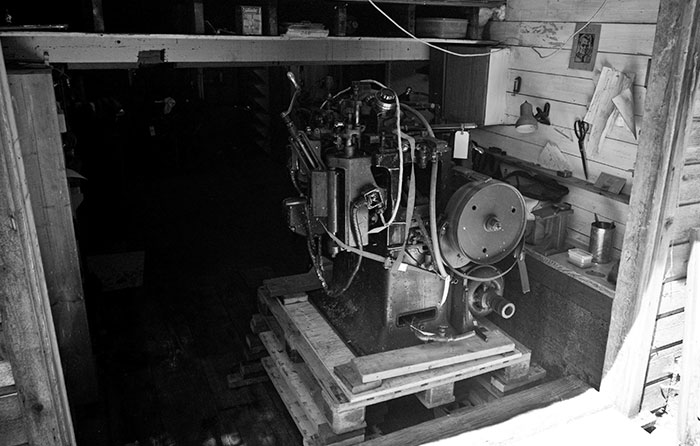

Finally, early in 2013, a move to a new house with a larger workspace allowed for the installation of most of Jim's stuff, including the Ogata pantograph (for engraving new matrices) and Jim's rare and extremely versatile Monotype Super Caster.

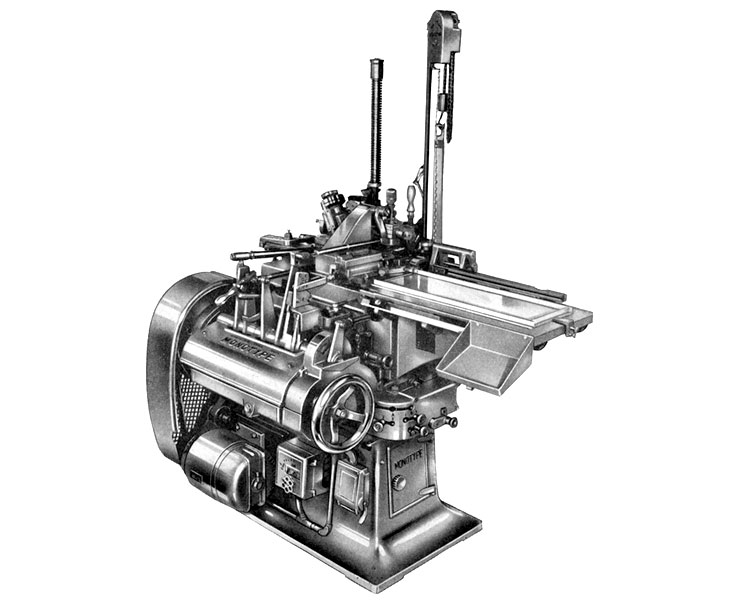

The Super really is a phenomenal machine, capable of casting type from 6-72pt, as well as spacing material, leads, rules and even furniture. Due to a non-competition agreement between Lanston Monotype (US) and the Monotype Corporation (UK), Super Casters were never imported to North America, but after both companies shut down a few Supers found their way across the pond. I know of only two of them in Canada, and a handful in the US, and they are extremely coveted by many who make their own type.

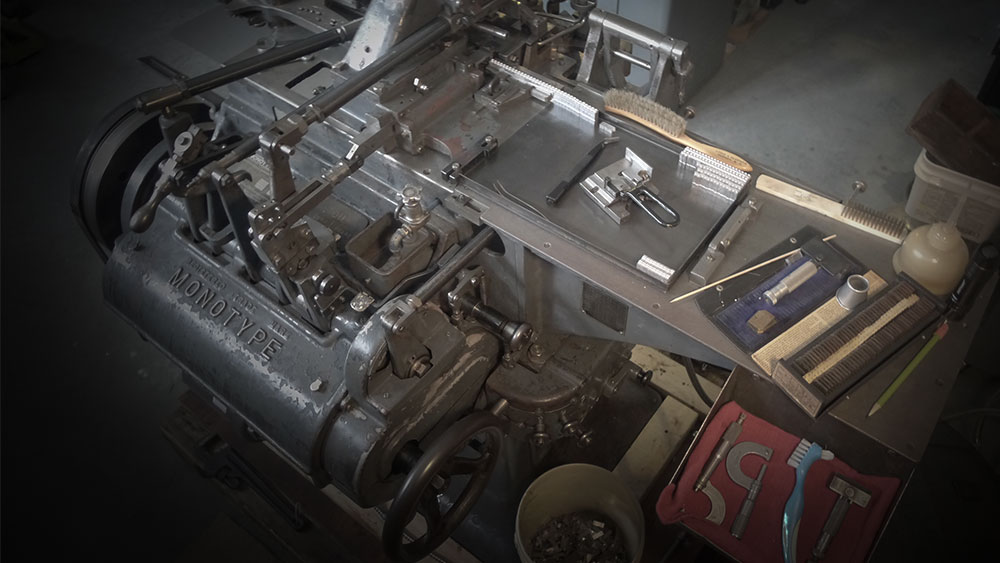

The Super Caster, melting pot, micrometer adjustment head and the delivery channel.

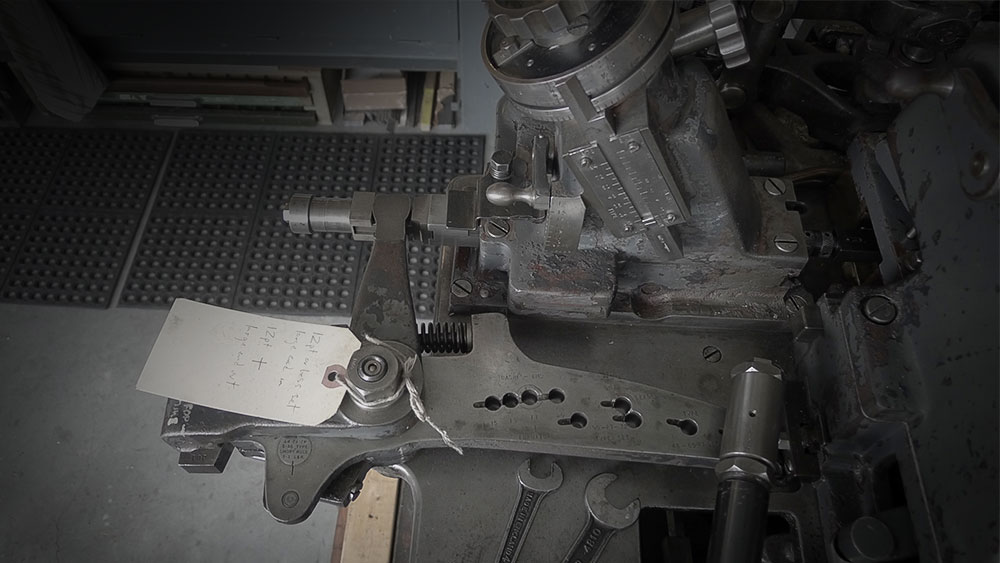

The Super's beauty lies not only in the breadth of product it can produce, but also in its relative simplicity of operation, especially when compared to the clockwork-complexity of the Composition Caster. I say this now, however, only after spending much of 2013 completely tearing down Jim's Super, cleaning it thoroughly, repairing and replacing a few parts, and putting it all back together. This was tackled during the summer months of 2013, and I then spent the autumn studying manuals, stumbling through a few weeks of trial-and-error experiments, as well as countless hundreds of emails to the very patient Rich Hopkins and Dan Jones, both Super Caster operators. Now that I've discovered, wrestled with, and solved a wide range of hiccups and blunders, now I can say that the Super is, in the end, a relatively simple machine to operate.

ATF matrices for Cloister Lightface, and a line of 14pt Chancery Italic type exiting the Super Caster.

One of the great pleasures of running this machine — aside from the obvious joy of operating a complex piece of equipment that one has spent hundreds of hours restoring, a machine with a rich history and astounding typographic output — is the slightly odd but also wonderful sense of accomplishment in getting Jim's machine functional again. I felt a certain anxiety taking on Jim's gear, given his herculean talent and inventiveness with these machines, his accomplishments and his legacy, but I must admit a lingering sensation that he's hanging around the shop with me, smiling and pointing, now and then, at a lever that needs adjusting, or nudging me when the pot starts to get low on metal.

I still have a long way to go, first to further develop my relationship with the machine, but then the next stage of my work with Jim's machines will begin, which will be to learn the necessary skills to engrave my own matrices with which to cast new type designs on the Super Caster. But, one thing at a time.

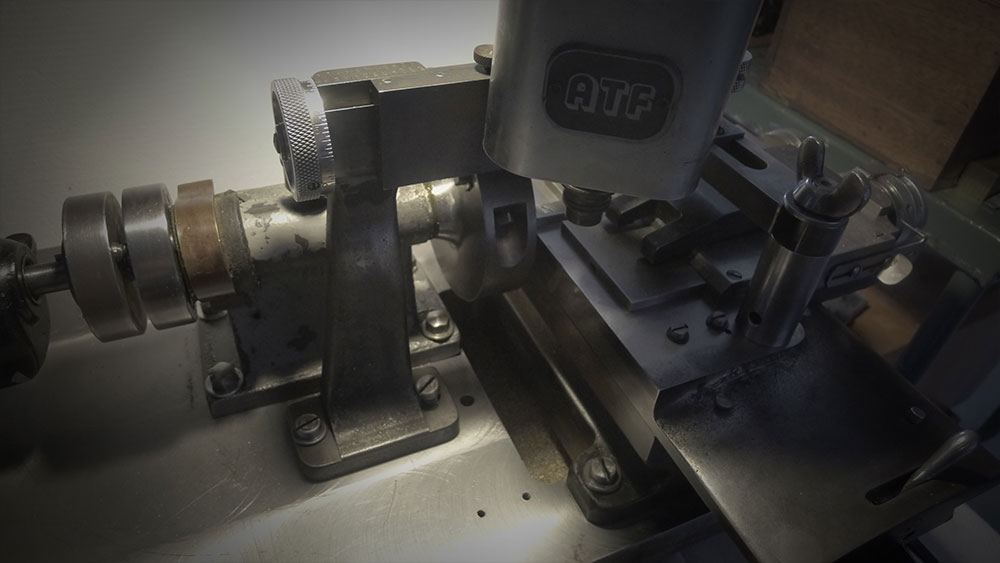

The Taylor Hobson and the Ogata pantographs, along with the ATF fitting machine and Monotype alignment microcsope.

While the Super Caster is the main weapon of choice in the typecasting room these days, I should also mention a few other important machines in the shop. Along with the Super, Jim's equipment also included his trusty Composition Caster, and his two much-envied pantographs: a stand-up Taylor-Hobson (which Jim used to cut lead patterns from paper patterns), and an Ogata (used to cut mats from the lead patterns). Along the way I also picked up a Monotype alignment microscope, and a very rare ATF fitting machine, used to prepare and fit brass matrices, as well as an equally rare ATF microscope, for measuring both cutting tools and finished matrices.